Maintenance of LPG Pump

VIEW MORE+

YanTai LangPu.

Product Center

Flotation equipment

Product Brief

HXDU rubber belt vacuum filter

Equipment Profile:

Rubber belt vacuum filter is a kind of high-efficiency separating equipment, which uses filter cloth as filter medium and makes full use of gravity settling and vacuum suction to realize solid-liquid separation.

Working principle:

Fixed vacuum box is used in the equipment. Ring rubber belt is driven by motor to run continuously on the vacuum box. The filter cloth is laid on the tape and runs synchronously with it. The tape contacts the friction belt on the sliding table of the vacuum box and forms a water-sealed structure. The slurry is evenly distributed on the filter cloth by the distributor. When the vacuum chamber is connected to the vacuum system, a vacuum suction zone is formed on the tape. The filtrate is collected through the transverse groove of the tape and enters the vacuum chamber through a small hole. Solid particles are intercepted on the filter cloth to form a filter cake. The liquid entering the vacuum chamber is discharged through the steam-water separator. As the rubber belt moves, the formed cake enters the cake washing area and the stage drying area in turn. Finally, the filter cloth is separated from the belt and the filter cake is discharged by a scraper at the discharging roller. The filter cloth discharged from the cake is regenerated after cleaning, and then re-enters the filter area after a set of backup rolls and deviation correction devices, and begins to enter a new filter.

Equipment features:

Equipment features:

1. It has a large capacity and can run continuously for 365 days.

2. Low failure rate and low maintenance cost (low vacuum loss).

3. The filter cake has low moisture content and low solid content. It can be discharged directly or reused.

4. Modular structure, simple operation and maintenance.

5. PLC + touch screen + automatic valve control, high degree of automation, can achieve unattended.

HXTC ceramic filter

Equipment Profile:

Ceramic filter is a kind of precision filtration equipment which can separate solid and liquid by vacuum negative pressure under capillary action of ceramic plate.

The solid suspended in the slurry tank is adsorbed on the ceramic plate under negative pressure. The liquid enters the inner cavity of the ceramic plate through the surface layer of the ceramic plate because of the vacuum pressure difference and the hydrophilicity of the ceramic plate, thus achieving the purpose of solid-liquid separation.

Working principle:

Working principle:

Under the action of vacuum negative pressure, the filter plate immersed in the slurry tank is capillary adsorbed through the filter plate, and a cake layer is formed on the surface of the filter plate. The filtrate is discharged from the filter plate through the pipeline to the drainage tank.

The rotor drives the filter plate and the filter cake adsorbed on the filter plate to the drying zone, and the filter cake continues to dehydrate under the action of vacuum. After the filter cake is dried, the rotor rotates to the discharging area (without vacuum) and discharges the material through a ceramic scraper. After discharging, the ceramic plate enters the backwash zone, and industrial water or compressed air enters the inner cavity of the ceramic plate through the backwash pipeline. The remaining fine materials in the inner hole of the ceramic filter plate are cleaned from inside to outside.

After working for a period of time, the ceramic plate is cleaned by the combination of ultrasonic wave and low concentration acid to ensure the efficient use of the ceramic plate.

Equipment features:

1. Compact structure, small area and low investment cost.

2. Low energy consumption and low operation cost.

3. The filter cake has low moisture and clear filtrate, which can be directly discharged or reused.

4. Use PLC + touch screen + automatic valve control, one-button boot-up, automatic operation control, save labor.

5. Solid-liquid separation meets environmental protection standards and saves energy and reduces consumption.

HXLY Intelligent Tower Filter Press

Brief introduction of equipment

HXLY intelligent tower filter press is a fully automatic, efficient and energy-saving high-tech solid-liquid separation equipment. The equipment uses the pressure of the pump, the gravity of the material and the effect of air pressure or water pressure to form a pressure difference on both sides of the filter cloth, so as to achieve efficient solid-liquid separation. Widely used in chemical industry, smelting oxide, electrolytic slag, leaching slag, slag dewatering of sewage sludge and waste acid treatment etc..

HXLY intelligent tower filter press is a fully automatic, efficient and energy-saving high-tech solid-liquid separation equipment. The equipment uses the pressure of the pump, the gravity of the material and the effect of air pressure or water pressure to form a pressure difference on both sides of the filter cloth, so as to achieve efficient solid-liquid separation. Widely used in chemical industry, smelting oxide, electrolytic slag, leaching slag, slag dewatering of sewage sludge and waste acid treatment etc..

Filter plate tower structure, filter cloth serpentine encircling horizontal filtration, multi-cylinder synchronized up and down operation, hydraulic cylinder self-guiding, compact structure, novel design: filtration, extrusion, washing, drying, unloading, filter cloth regeneration whole operation process can be continuously and automatically completed. The filtration pressure can reach 20 MPa, which has remarkable effect on various sticky and fine materials and on occasions requiring low moisture of filter cake. The equipment is operated by full hydraulic control, which is stable, reliable and has high safety factor. PLC + touch screen + automatic valve control, simple operation, high degree of automation. 滤饼水分低、生产能力大,工作效率是传统液压机的几倍甚至十几倍。

Working principle

When the filter plate and frame are closed, the slurry enters each filter chamber through the slurry tube at the same time. The filtrate enters the filter chamber through the filter cloth, then enters the filter hose, and finally reaches the main filter tube to discharge.

The high-pressure water enters the upper part of the diaphragm through the high-pressure water hose at one time, and the diaphragm extrudes the filter cake to the surface of the filter cloth, thereby extruding the filtrate out of the filter cake.

Washing (optional stage): The washing liquid is pumped to the filter chamber using the same pipe as the slurry. As the liquid fills the filter chamber, the diaphragm is lifted and the high-pressure water above the diaphragm is squeezed out. The washing liquid flows into the discharge pipe after passing through the cake and cloth.

Secondary extrusion (optional stage) The detergent remaining in the filter chamber after the washing stage is extruded using the method described in the second stage.

Air drying: The final drying of filter cake is done by compressed air. The air entering through the distribution pipe is filled with the filter chamber, and the diaphragm is lifted so that the high-pressure air on the diaphragm is discharged from the filter press. By reducing the air flow of the filter cake, the moisture content of the filter cake reaches the optimum level, and the filter cavity is emptied at the same time.

Discharge of filter cake: When the drying process is completed, the plate and frame components are opened, the filter cloth driving mechanism starts to run, and the filter cake on the filter cloth is discharged from both sides of the filter press.

Product characteristics:

1. PLC + touch screen + automatic valve control, simple operation, high degree of automation, one key operation, can achieve unattended.

2. The cycle is short, the production capacity is large and the moisture content of filter cake is low. The working efficiency is several times or even more than ten times of the traditional hydraulic press.

3. The filtration pressure can reach 20 MPa, which has a remarkable effect on various sticky and fine materials and on occasions requiring low moisture content of filter cake.

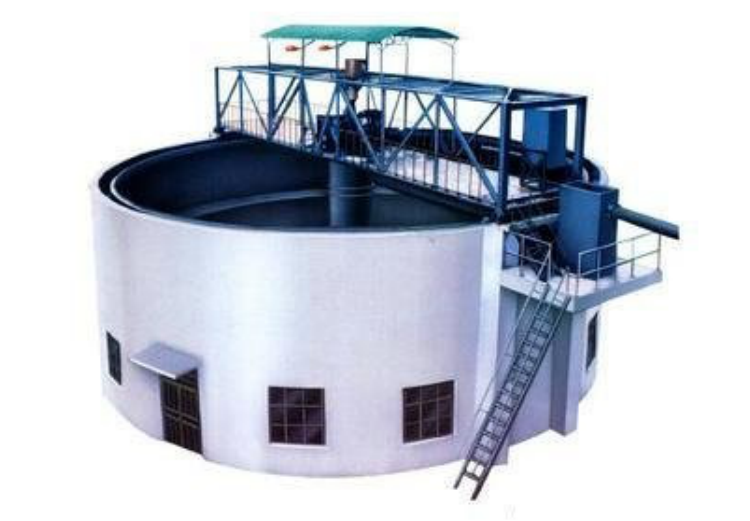

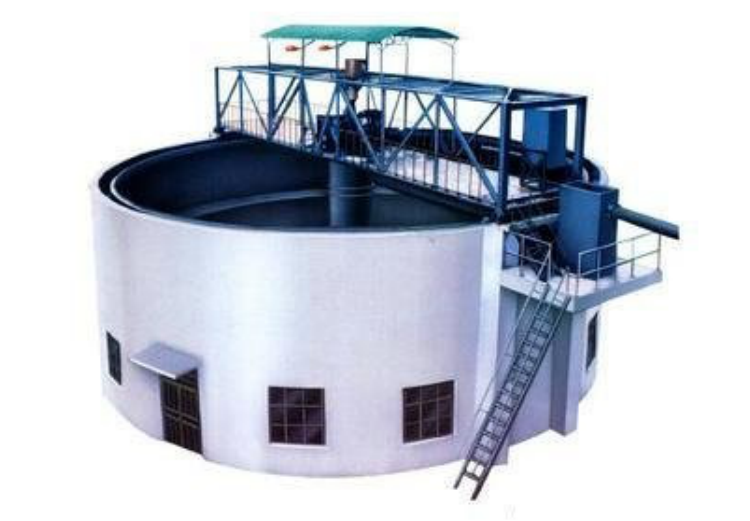

HXNGZ High Efficiency Thickener

设备简介:

HXNGZ高效浓密机采用圆形池体,变坡池底或深锥池底,可实现深层压缩,且变坡池底可加速高效浓缩底流向中心的刮集速度;使浓缩效率大大加快。浓缩效率是普通浓密机的3-8倍,底流浓度可以达到60-70%。

设备简介:

高能力的驱动系统和驱动保护系统。

旋转耙架采用低速液压马达或驱动电机通过一个高效行星齿轮箱来驱动,耙架提升通过提升机构,由若干平行运行的液压缸或提升减速机来提升旋转耙架,以达到驱动卸载、减负荷的目的,从而使驱动系统得以保护。

高效的给料系统具有完成给料矿浆充分脱气、矿浆的进料速率控制、絮凝剂用量的控制等功能。

刮泥耙叶片形式采用对数螺旋线分布的弧形刮泥耙叶片,收集效率高、旋转耙运行阻力小。

设备用途

浓密机是我公司引进国外技术研制的一种新型中心传动、自动提耙高效浓密机;广泛应用于尾矿处理、湿法冶炼、环境工程选矿等众多领域。

Related news

-

-

Precautions before operation of electric scraper

VIEW MORE+ -

Three-Point Power System of Diesel Scraper

VIEW MORE+

TEL:136-0545-5667

Contact:Mr.Fan

Addr:烟台市芝罘区通润路1号

Email:503104313@qq.com

Friendship link:

ThinkCMF

Yantai Lamp Import and Export Co., Ltd.